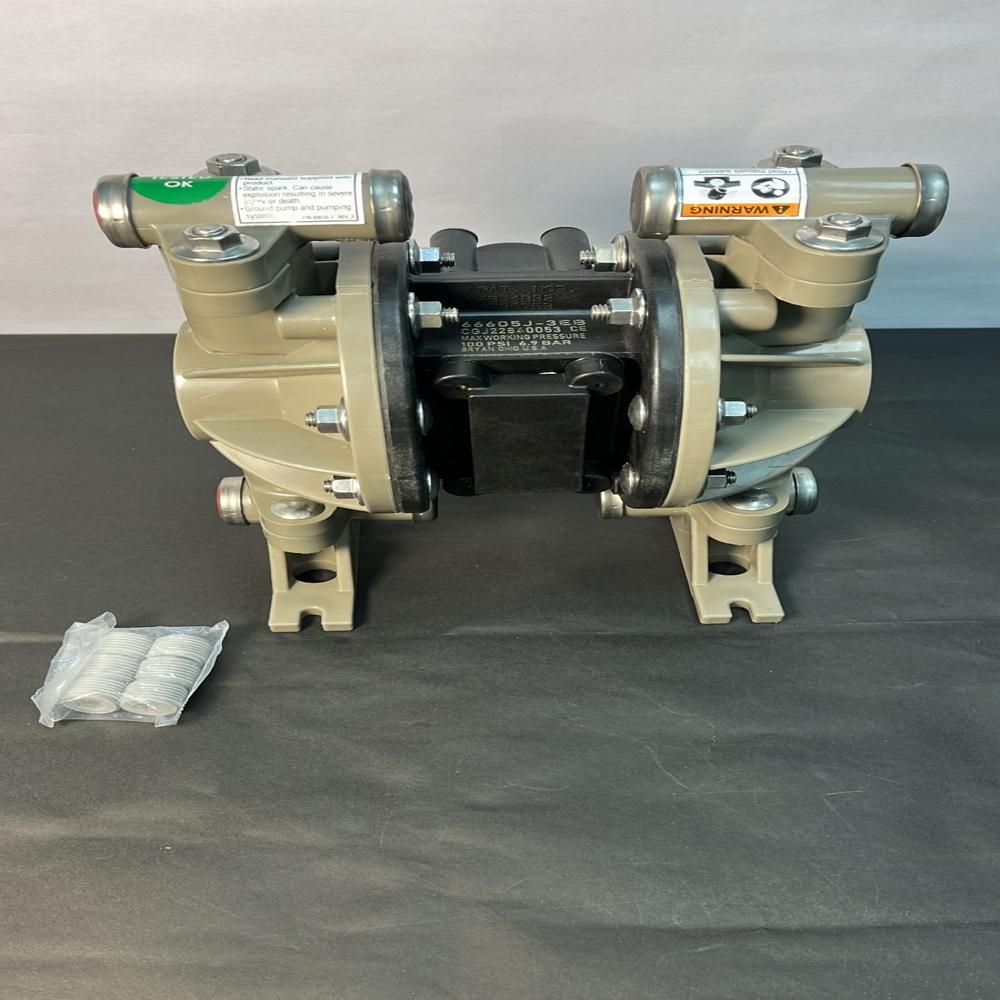

Anilox Coater Pump

Price 25000.0 INR/ Unit

Anilox Coater Pump Specification

- Flow Rate

- 49 50 LPM

- Features

- High Quality

- Usage

- Chemical Transfer, Water Treatment, Printing, Coatings, Industrial Fluids

- Material

- Polypropylene (PP) & Teflon (PTFE)

- Structure

- Diaphragm Pump

- Size

- 1/2" (Dual Inlet/Outlet Configuration)

- Height

- 7 Inch (in)

- Weight

- 7 Kilograms (kg)

- Width

- 12 Inch (in)

- Length

- 14 Inch (in)

Anilox Coater Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 3 Days

- Main Domestic Market

- All India

About Anilox Coater Pump

| Specification | Details |

|---|---|

| Brand | ARO |

| Pump Type | Air Operated Double Diaphragm Pump (AODD) |

| Inlet / Outlet Size | 1/2(Dual Inlet/Outlet Configuration) |

| Maximum Flow Rate | 49 50 LPM |

| Material of Construction (MOC) | Polypropylene (PP) & Teflon (PTFE) |

| Wetted Parts | Polypropylene (PP) |

| Power Source | Pneumatic (Compressed Air) |

| Operation | Air-Operated, Non-Electric |

| Applications | Chemical Transfer, Water Treatment, Printing, Coatings, Industrial Fluids |

Applications Industries Served

This pump is widely used in

Chemical Processing acids alkalis corrosive liquids

Water Wastewater Treatment

Printing Coating Applications anilox coating ink handling

Industrial Fluid Handling safe for flammablevolatile fluids

Pharmaceuticals Food Industrywhere nonmetallic materials are required

Why Choose ARO AODD Pumps

Long service life with minimal maintenance

Reliable performance in tough environments

Safe alternative to electric pumps for hazardous fluids

Easy installation and operation

Exceptional Durability and Performance

Built using premium Polypropylene PP and Teflon PTFE the Anilox Coater Pump is engineered to withstand harsh chemicals and demanding operations Its pneumatic drive system provides powerful and consistent flow essential for industrial uses in printing coatings and water treatment

Versatile Application Range

With a dual 12inch inletoutlet configuration the pump adapts effortlessly to various setups Whether transferring industrial fluids treating water or handling chemical distribution its broad usage spectrum makes it suitable for diverse industries

Reliable Flow for Critical Processes

Delivering a steady flow rate of 4950 LPM under high pressure the Anilox Coater Pump ensures dependable supply without fluctuations This consistency enhances process reliability safeguarding productivity and reducing downtime

FAQs of Anilox Coater Pump

Q How is the Anilox Coater Pump typically installed for industrial use

A Installation involves connecting the 12 dual inletoutlet to the appropriate fluid lines using compatible fittings Its pneumatic operation requires access to a compressed air source making setup straightforward in most industrial environments

Q What materials are used in the construction of this pump and why are they chosen

A The pump is built from Polypropylene PP and Teflon PTFE selected for their outstanding chemical resistance and durability These materials help ensure safe operation and longevity particularly in corrosive and demanding fluid environments

Q When is it advantageous to use this pump in water treatment or chemical processes

A This pump is ideal when high flow rates and robust chemical handling are necessary such as in water treatment plants laboratories or facilities dealing with harsh industrial chemicals

Q Where can the Anilox Coater Pump be supplied from

A The pump is manufactured and supplied by leading industrial equipment providers in India offering reliable distribution to both domestic and international industrial customers

Q What is the main process supported by this pump in the printing and coatings industry

A It facilitates the precise and consistent transfer of coatings and inks ensuring uniform application and minimizing waste due to its controlled highpressure operation

Q How does the dual inletoutlet configuration benefit industrial operations

A The dual inletoutlet design provides flexibility in system integration allowing for efficient circulation and transfer of fluids and supporting continuous operation without frequent reconfiguration

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Diaphragm pump Category

Tresu - Air Operated Double Diaphragm Pump (AODD)

Price 25000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Size : 1/2" (Dual Inlet/Outlet Configuration)

Usage : Chemical Transfer, Water Treatment, Printing, Coatings, Industrial Fluids

Height : 7 Inch (in)

Flow Rate : 49 50 LPM

Tresu AODD Pump

Price 25000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Size : 1/2" (Dual Inlet/Outlet Configuration)

Height : 7 Inch (in)

Flow Rate : 49 50 LPM

Tresu AOD Pump

Price 25000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Size : 1/2" (Dual Inlet/Outlet Configuration)

Height : 7 Inch (in)

Flow Rate : 49 50 LPM

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry