Albatross UV Tube

Price 11711.0 INR/ Unit

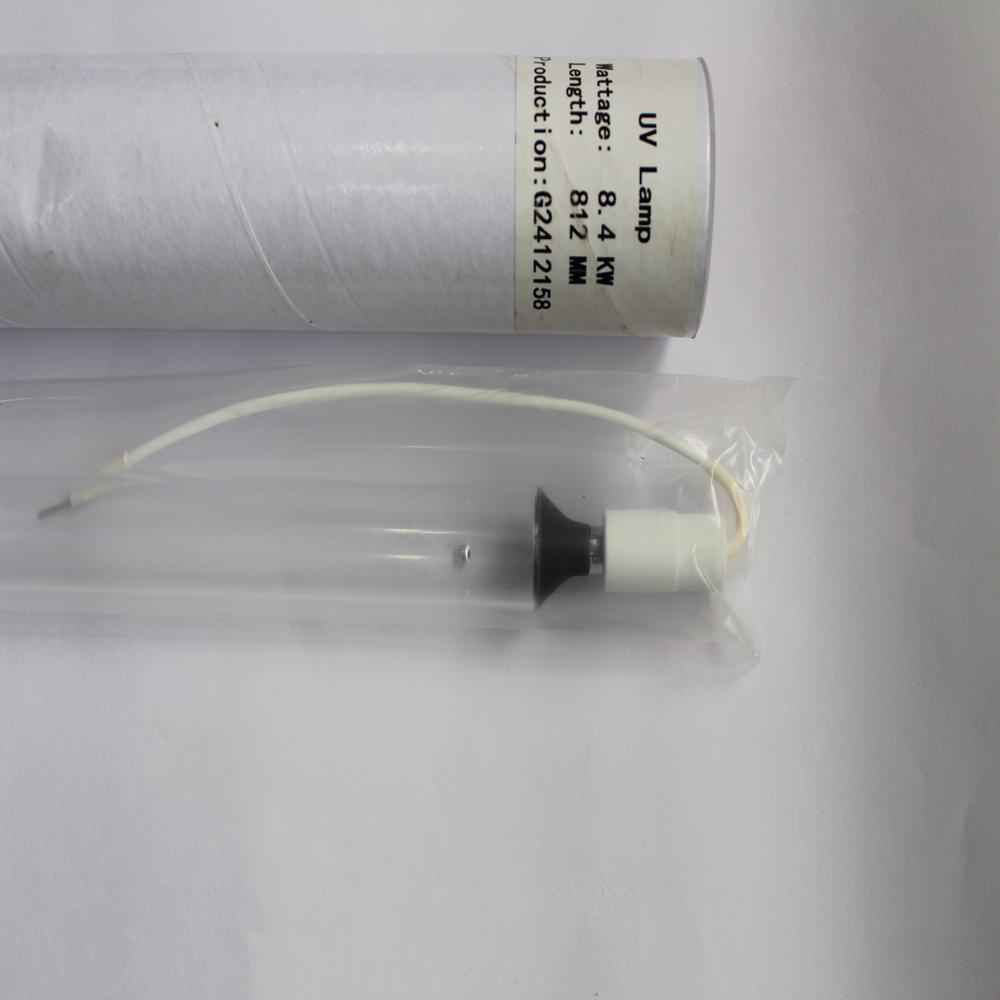

Albatross UV Tube Specification

- Usage & Applications

- Offset, Flexographic, Gravure, Digital Inkjet, Screen, and Packaging Printing

- Weight

- Differ as per size Grams (g)

- Voltage

- 220 - 1900 Volt (v)

- Warranty

- Yes

- Dimension (L*W*H)

- Cable lenth-285 Millimeter (mm)

Albatross UV Tube Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Albatross UV Tube

Specification

| Size | Total Length (mm) | Arc Length (mm) | Diameter (mm) | End Fitting Style | Terminal Type | Cable Length (Left mm) | Cable Length (Right mm) | Voltage | Current (A) | Power (KW) |

| 25"/300 | 805 | 635 | 25 | B | Pin Type | 285 | 285 | 900 | 8.8 | 7.5 |

| 28"/300 | 812 | 711 | 25 | B | Pin Type | 285 | 285 | 1000 | 8.4 | 8.4 |

| 30"/300 | 914 | 762 | 25 | B | Pin Type | 285 | 285 | 1000 | 9.8 | 9 |

| 36"/300 | 1016 | 914 | 25 | B | Pin Type | 285 | 285 | 1200 | 9 | 10.8 |

| 40"/400 | 1168 | 1016 | 25 | B | Pin Type | 285 | 285 | 1500 | 10.6 | 16 |

Available in around 200 different sizes, with customized sizes also available.

Precision UV Curing Across Printing Technologies

The Albatross UV Tube provides consistent, high-quality curing for multiple printing technologies such as offset, flexographic, gravure, and screen printing. Its adaptability makes it a popular choice for modern packaging and graphic applications, ensuring vibrant and durable finishes.

Robust Engineering for Industrial Demands

With a cable length of 285 mm and a design that adapts to various sizes and weights, the Albatross UV Tube accommodates different machine configurations. Its automatic control mode streamlines operation, increasing efficiency and reducing manual intervention in the printing process.

FAQs of Albatross UV Tube:

Q: How is the Albatross UV Tube used in different printing processes?

A: The Albatross UV Tube is designed to cure inks and coatings in a variety of printing applications, including offset, flexographic, gravure, digital inkjet, and screen printing. It ensures rapid and uniform curing of printed materials, enhancing print quality and production speeds.Q: What are the main benefits of using the Albatross UV Tube?

A: Key benefits include efficient UV curing, compatibility with several printing technologies, automatic control for ease of use, and robust construction with warranty support. These features combine to deliver vibrant prints and increased productivity in industrial settings.Q: Where can the Albatross UV Tube be installed?

A: This UV tube can be integrated into printing machinery for offset, flexographic, gravure, screen, digital inkjet, and packaging printing setups. Its size and weight variations ensure a suitable fit for a range of industrial applications.Q: When should the Albatross UV Tube be replaced?

A: Replacement intervals depend on usage hours and printing intensity. Its advisable to monitor performance and consult with the manufacturer for scheduled maintenance or if you observe diminishing UV curing effectiveness.Q: What is the process for installing the Albatross UV Tube?

A: Installation involves connecting the UV tube to the appropriate fixture in your printing machinery, utilizing its 285 mm cable. It operates on 220 - 1900 Volt power and should be handled by qualified personnel to ensure safety and optimal integration.Q: How does the automatic control mode enhance usage?

A: The automatic control mode regulates UV tube operation without the need for constant human supervision, providing consistent curing results and energy efficiency while minimizing operator workload.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in UV Lamp Category

Albatross Ultraviolet lamp

Price 11711.0 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Uv Lamp

Warranty : Yes

Model No : Albatross

Voltage : 220 1900 Volt (v)

Albatross UV Curing Lamp 28"/300 (812 mm)

Price 12357.0 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : UV Curing Lamp

Warranty : 1 Year

Model No : ALBUV28/300812

Voltage : 1000 Volt (v)

Albatross UV Tube 805 mm

Price 11714.0 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Uv Lamp

Warranty : 1 Year

Model No : UV6357K5900VB2P

Voltage : 900 Volt (v)

Albatross UV Tube 914 mm (30"/300)

Price 12776.0 INR / Piece

Minimum Order Quantity : 1 Unit

Product Type : Curing Lamp

Warranty : 1 Year

Model No : UV7629K01000VB2P

Voltage : 1000 Volt (v)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry